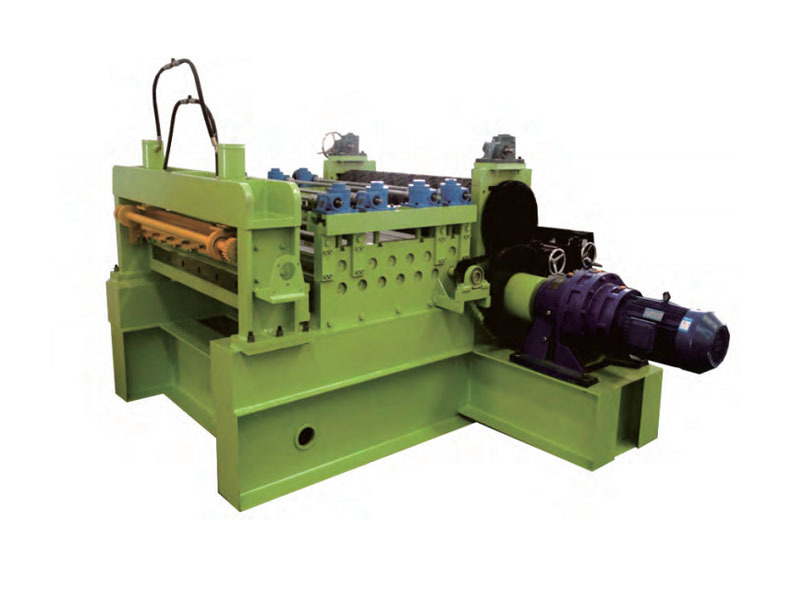

The 100-300 Type Z-Steel Purlin Forming Machine uses a continuous cold-bending process to transform raw materials such as galvanized steel sheets or color-coated steel sheets into steel purlins with a specific cross-sectional shape (Z-shaped). This equipment features high efficiency, stability, and a high degree of automation, making it capable of meeting large-scale production demands.

Stable Quality: Thanks to precise roller design and advanced forming processes, the accuracy and surface quality of the purlins are consistently stable and reliable.

Energy-saving and environmentally friendly: Utilizing cold-forming technology eliminates the need for heating, significantly reducing energy consumption. At the same time, the production process generates minimal waste, aligning perfectly with environmental protection standards.

Easy operation: Equipped with an advanced electronic control system, it’s simple and intuitive to operate, significantly reducing workers' physical labor intensity.

Easy maintenance: The equipment features a reasonably designed structure that makes maintenance and upkeep straightforward. Key components such as rollers and spindles are standard parts, ensuring they’re easy to replace and repair.

About Zhanda

Botou Zhanda Cold Bending Machinery Equipment Co., Ltd. is located in the "Hometown of Chinese Casting" -- Botou Development Zone, Hebei Province. It has a superior geographical location, bordering Beijing-Tianjin to the north, Bohai (Huanghua Port) to the east, 200 kilometers west to Shijiazhuang, and south to Jinan. The Beijing-Shanghai high-speed railway, expressways, and National Highway 104 run through the city, making transportation very convenient.

Main products: composite machines, floor deck machines, hydraulic driven steel machines, wall forming machines, ceiling panel forming machines, advertising buckle machines, hydraulic bending machines, hydraulic shearing machines, slitting machines, various feeding racks, packing boxes, quick-assembly boxes, container-type cold bending forming machines, wholesale quick-assembly house frame profiles, various mechanical parts, and customizable special-shaped color steel tile pressing equipment.

Through practical experience and the dedicated design of technical personnel, our company has developed into a modern enterprise integrating production, sales, installation, commissioning, and providing tile pressing machine technical consulting. Our products are sold nationwide and highly praised by users.

All employees of our company warmly welcome friends from all walks of life and new and old users to visit, guide, negotiate cooperation, work together for common development, and create brilliance.

Service process

Customer inquiry

Factory quotation

Customer order

Factory production

Quality testing

Packaging and transportation

FAQ

Can you accept a small quantity?

Do you have a pre-shipment inspection procedure?

Can I take a sample for testing?

When is the delivery time?

What are the payment terms?

Can I have my own custom product?