Product Series

Contact Us

Email:

WhatsApp:

WhatsApp:

Address:

Xing Village, Shibawu, Botou Town, Cangzhou City, Hebei Province

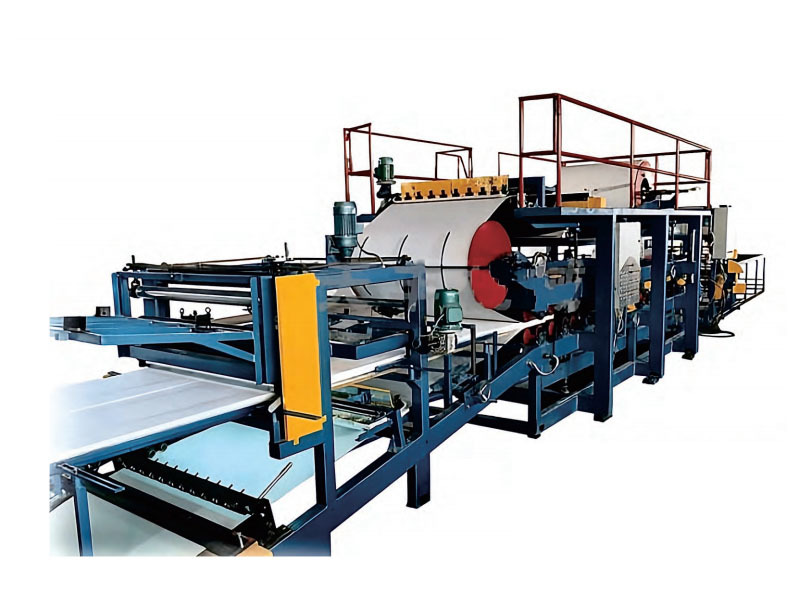

Insulation Composite Panel Production Line

Insulation Composite Panel Production Line

The F-type production line employs advanced manufacturing processes that integrate pneumatic, electrical, and mechanical systems. It is specialized equipment designed for processing color steel insulated composite panels. The working speed is regulated by variable-frequency stepless adjustment, enabling the machine to produce corrugated composite panels in a single operation. The complete production line consists of a material-feeding mechanism, a profiling unit, and a composite assembly system (including rib pressing, adhesive application, heating, lamination, edge rolling, slotting, edge trimming, and pneumatic automatic cutting). This equipment is essential for manufacturing roof and wall panels used in industrial plants, warehouses, and other similar structures.