2025-08-25

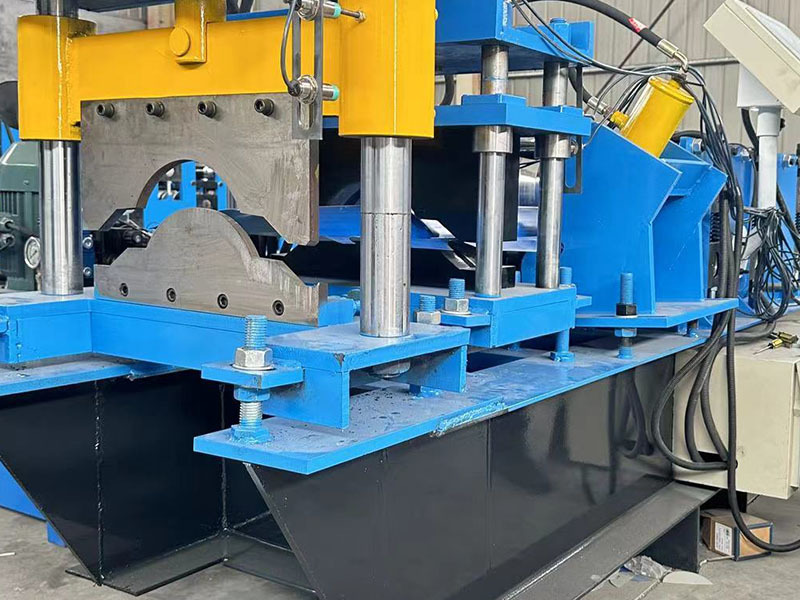

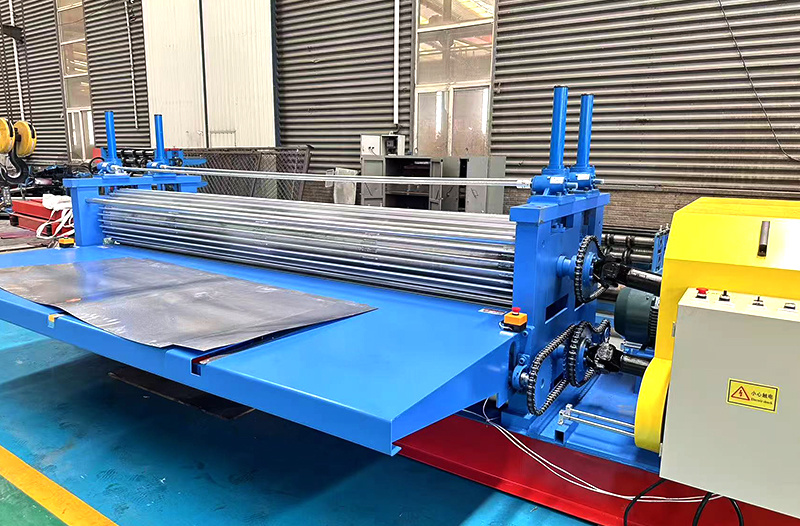

Working Principle of Hydraulic Driven Steel Machine

The hydraulic-driven section steel machine converts mechanical energy into hydraulic energy through a hydraulic pump, generating high-pressure oil. This high-pressure oil is transmitted through hydraulic pipelines to hydraulic cylinders or hydraulic motors, driving actuators (such as rollers, molds, etc.) to perform processing operations on the section steel, including bending, straightening, cutting, and punching. The pressure, flow, and direction of the hydraulic system can be precisely controlled by hydraulic valves, enabling accurate processing of the section steel.

2025-08-25

Characteristics of hydraulic-driven steel machines

High pressure, large thrust: The hydraulic system can generate high-pressure oil to drive the actuator to produce large thrust, meeting the high-strength requirements of steel profile processing.

2025-08-25

Selection and Use of Hydraulic Driven Steel Machines

Select the appropriate type and specification of the section steel machine according to processing requirements to ensure the equipment can meet production demands. Examine the performance of the equipment's hydraulic system, such as pressure, flow, and stability, to ensure the equipment has sufficient processing capacity.

2025-09-27

Digging Deep: The Marvels of the ditch digging machine

Discover the innovations behind ditching machines and how they transform excavation work.

2025-09-27

Digging Deep: Unveiling the Wonders of the Ditching Machine

Explore the innovative ditching machine designed for efficiency and versatility in excavation tasks.

2025-09-27

Digging Deep: The Marvels of the Ditching Machine

Discover the ins and outs of a ditching machine, its uses, and how it revolutionizes excavation work!

2025-09-28

Unveiling the Secrets of the Ditching Machine: How It Works

Discover the fascinating workings of the Ditching Machine and its vital role in construction.

2025-09-28

Mastering the Art of Ditching Machines: Key Considerations for Success

Explore essential tips and insights for using ditching machines safely and effectively.

2025-09-28

The Versatile ditch digging machine: Uncovering Its Applications

Explore the various applications of the ditching machine across industries and how it transforms tasks.

2025-09-29

Revolutionizing Construction: The Role of Ditching Machines in Modern Industry Solutions

Discover how ditching machines are transforming the construction industry with innovative solutions.

Contact Us

Email:

WhatsApp:

WhatsApp:

Address:

Xing Village, Shibawu, Botou Town, Cangzhou City, Hebei Province