Definition and Working Principle of Cold Bending Equipment

2025-08-18

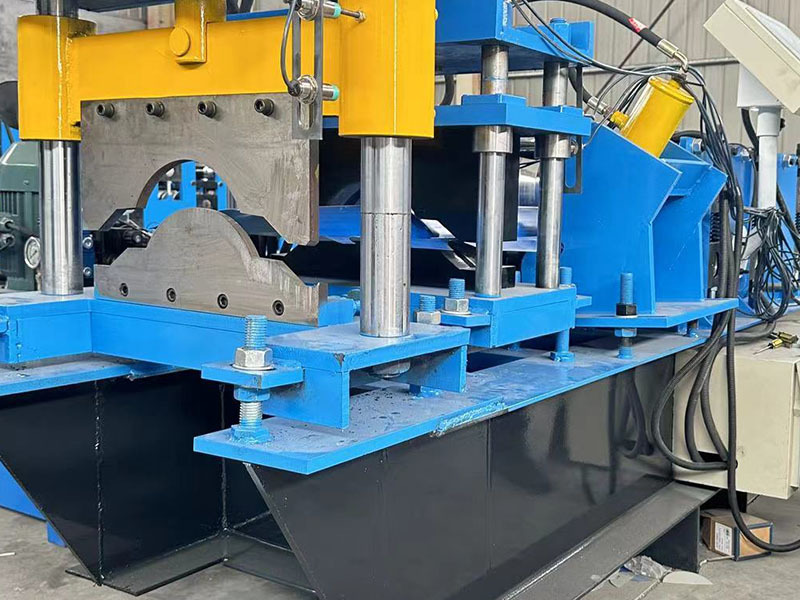

Cold bending equipment is a type of machinery that continuously bends metal sheets (such as coils and strips) into specific cross-sectional shapes through pressure. Its core process is continuous bending forming, applying pressure to the metal through multiple sets of rollers or molds, causing plastic deformation at room temperature to form the required profiles (such as C-shaped steel, U-shaped steel, special-shaped sections, etc.).

Typical workflow:

Feeding: Metal sheets are fed into the equipment through auxiliary systems (such as gantry supports).

Bending: The hydraulic system or mechanical drive powers the rollers/molds to apply pressure to the sheet, gradually bending it to the designed curvature.

Discharge: The formed profiles are continuously output, completing the processing.

Advantages:

Energy-saving and environmentally friendly: No heating required, reducing energy consumption.

High material utilization: Reduces cutting allowance, saving raw materials.

High forming accuracy: Suitable for producing complex cross-sectional profiles.

Previous Article:

Contact Us

Email:

WhatsApp:

WhatsApp:

Address:

Xing Village, Shibawu, Botou Town, Cangzhou City, Hebei Province