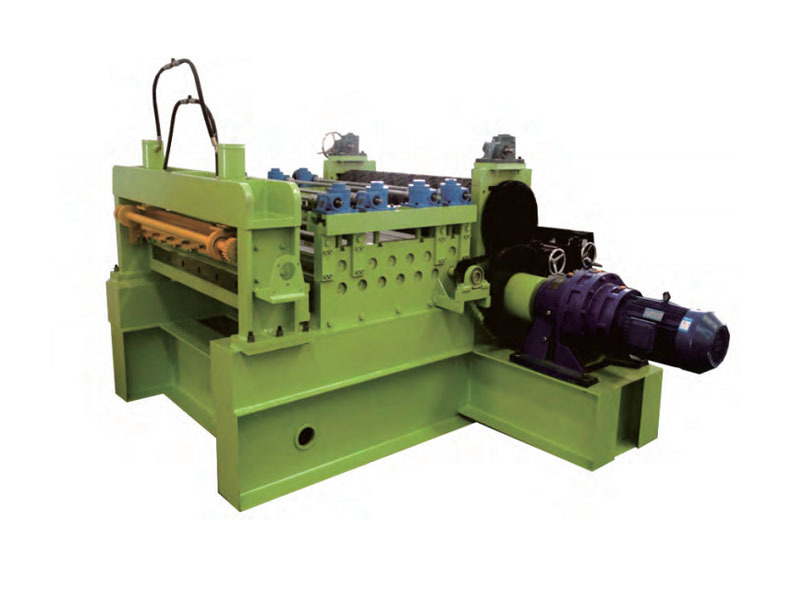

The F-type production line employs advanced manufacturing processes that integrate pneumatic, electrical, and mechanical systems. It is specialized equipment designed for processing color steel insulated composite panels. The working speed is regulated by variable-frequency stepless speed control, enabling the machine to produce corrugated composite panels in a single operation. The complete production line consists of a material-feeding mechanism, a profiling unit, and a composite unit (including rib pressing, adhesive application, heating, lamination, edge rolling, slotting, edge trimming, and pneumatic automatic cutting). This equipment is essential for manufacturing roof and wall panels used in industrial plants, warehouses, and other similar structures.

|

|

|

|

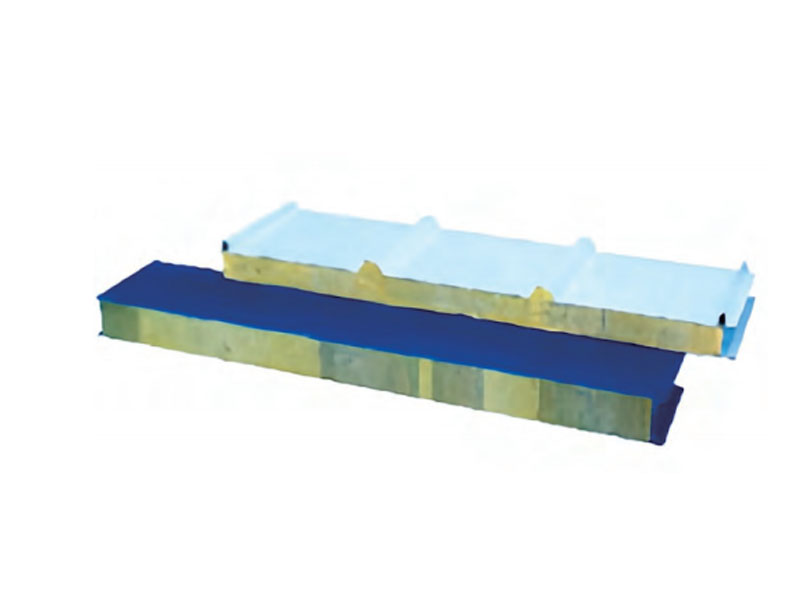

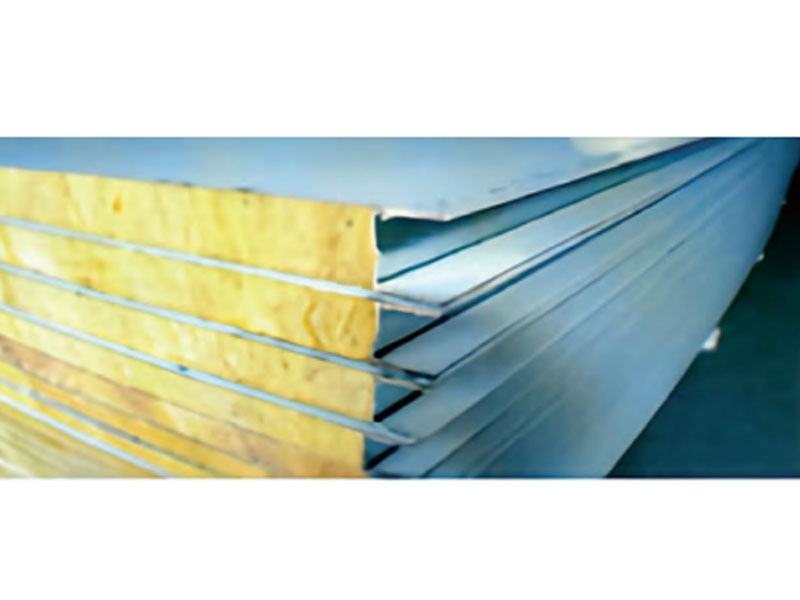

| Expanded Polystyrene (EPS) Composite Board Series | Glass Fiber Cotton Sandwich Panel Series | Rockwool Sandwich Panel Series | Polyurethane Sandwich Panel Series |

Product Specifications

| Power supply | 380V / 50 to 60Hz |

| Total Power | 32kw |

| Production line speed | 0-4m/min |

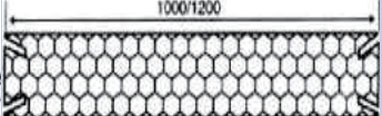

| Product width | 1000mm or 1200mm |

| Product Thickness | 50-250mm |

| Annual production | 600000m2 Per year |

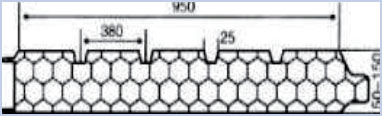

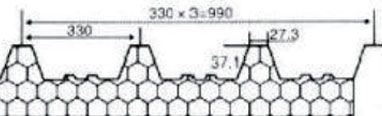

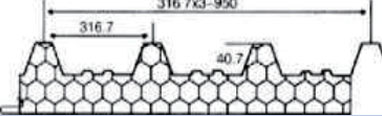

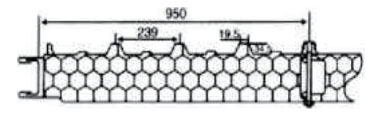

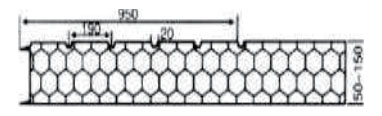

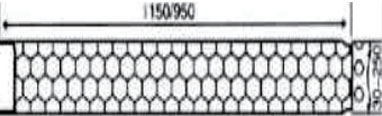

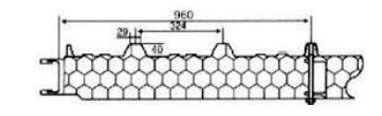

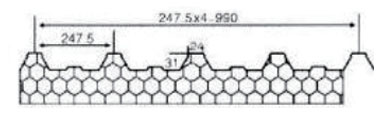

| T950 Wall Panel with EPS Core Material | T990 Middle Peak | T950 Medium-Two-Peak Overlapping Corrugated Board | EPS Core Material Insert Connection |

|

|

|

|

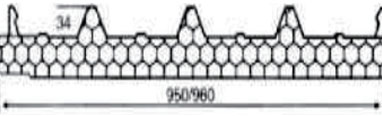

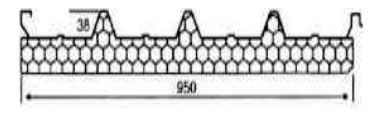

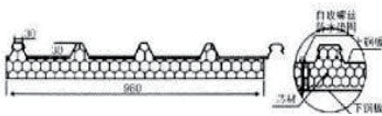

| 950/960 Mid-Three-Peak Hidden (Cap-Type) Corrugated Board | G950, Insulation Cotton Core Material (Cap-Type) | Small corrugated wall panels with EPS core material | 950 Medium-Height Three-Peak Interlocking Corrugated Sheet |

|

|

|

|

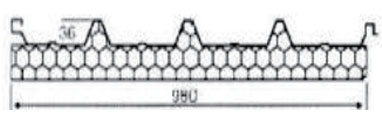

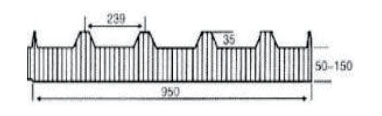

| 980 Mid-Three-Peak Self-Locking Corrugated Sheet | EPS Core Material Tongue-and-Groove Board | 980 Mid-Range Four-Peak Splice Corrugated Panel | G960, Insulation Cotton Core Material |

|

|

|

|

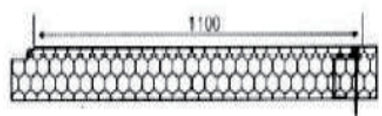

| T990 Middle Three Peaks | 1100 Hidden Wall Panel with EPS Core | 980 Mid-Three-Peak Interlocking Corrugated Panel | 950 Hidden Corrugated Board Fire-Resistant Material |

|

|

|

|

Keyword

About Zhanda

Botou Zhanda Cold Bending Machinery Equipment Co., Ltd. is located in the "Hometown of Chinese Casting" -- Botou Development Zone, Hebei Province. It has a superior geographical location, bordering Beijing-Tianjin to the north, Bohai (Huanghua Port) to the east, 200 kilometers west to Shijiazhuang, and south to Jinan. The Beijing-Shanghai high-speed railway, expressways, and National Highway 104 run through the city, making transportation very convenient.

Main products: composite machines, floor deck machines, hydraulic driven steel machines, wall forming machines, ceiling panel forming machines, advertising buckle machines, hydraulic bending machines, hydraulic shearing machines, slitting machines, various feeding racks, packing boxes, quick-assembly boxes, container-type cold bending forming machines, wholesale quick-assembly house frame profiles, various mechanical parts, and customizable special-shaped color steel tile pressing equipment.

Through practical experience and the dedicated design of technical personnel, our company has developed into a modern enterprise integrating production, sales, installation, commissioning, and providing tile pressing machine technical consulting. Our products are sold nationwide and highly praised by users.

All employees of our company warmly welcome friends from all walks of life and new and old users to visit, guide, negotiate cooperation, work together for common development, and create brilliance.

Service process

Customer inquiry

Factory quotation

Customer order

Factory production

Quality testing

Packaging and transportation

FAQ

Can you accept a small quantity?

Do you have a pre-shipment inspection procedure?

Can I take a sample for testing?

When is the delivery time?

What are the payment terms?

Can I have my own custom product?